The cycling market today is very competitive, and the brands do not only require manufacturing capacity. They require someone who is knowledgeable about performance engineering, material science, quality control, and world standards. HaideliBikes has proven itself to be one of the reputable professional carbon fiber bike frame manufacturers offering OEM and custom molding solutions that turn ideas into high-performance carbon bike frames. HaideliBikes makes sure that there is accuracy, uniformity, and quality throughout the design process, from mass production to the last review.

Understanding the Brand Concept

HaideliBikes OEM projects start with thorough knowledge of the brand vision of the client. The design of an aerodynamic road frame, a robust gravel frame, or a lightweight mountain bike frame all have their respective engineering team liaising with the brand and determining the performance metrics, rider application, geometry choices, and compliance criteria. Early involvement in the cooperation process makes sure that the end product is in accordance with the market position as well as the real-life requirements of the ride.

This is a stage where the main parameters, including frame size range, the stiffness objectives, weight objectives, and the standards to be achieved, e.g., ISO or EN, are identified. It is a basis on which the development process can proceed efficiently and accurately.

Design and Engineering Development

After completing the concept, the engineering department of HaideliBikes proceeds to the development of the detailed design. Engineers can develop the optimal geometry, structural integrity and manufacturability of the carbon bike frame by creating accurate 3D representations using sophisticated CAD tools. Special consideration is paid to stress points, including the head tube, bottom bracket, and the rear triangle, because all of them directly influence the feeling and power delivery.

Computer programs like CFD can be used with aerodynamic frames, whereas the design of suspension pivots is ideal with full-suspension models. This is an engineering-oriented design that guarantees that performance is incorporated into the frame at the very early stage, as opposed to being revised.

Carbon Layup and Material Selection

Carbon fiber layup design has been among the most essential factors in the production of carbon bike frames. HaideliBikes pays much attention to the choice of carbon fiber grades by taking into account the necessary strength, stiffness, and weight. The schedules of layups are customized in different parts of the frame to achieve a balance of rigidity and compliance.

Engineers also decide the fiber orientation, layer thickness and reinforcement areas to bring about optimum performance under the actual running circumstances. This is the exact lay-up plan. This means that HaideliBikes will manufacture lightweight frames, but at the same time, can resist the long-term fatigue and impact force.

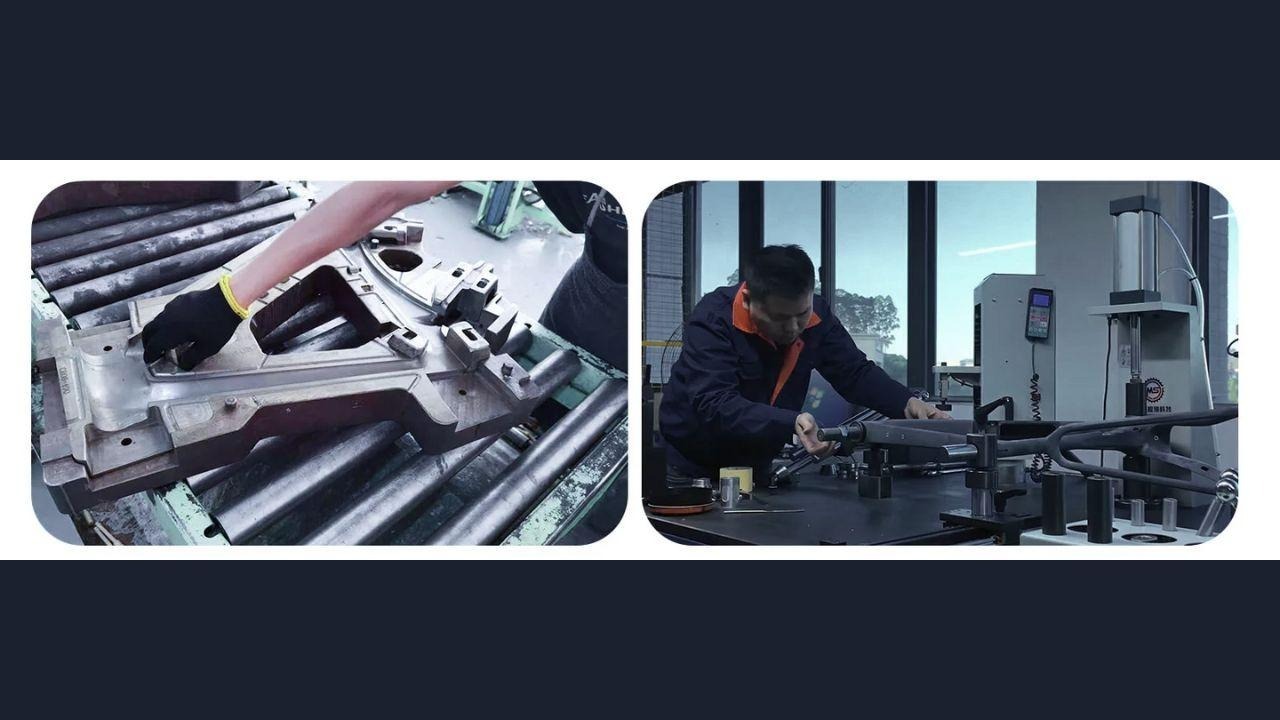

Mold Development and Prototyping

Once design validation is completed, high-precision tooling is used to make molds. The accuracy of the mould directly influences the alignment of the frame, the quality of the surfaces and the stability of the production batch-to-production-batch consistency. To attain dimensional consistency and repeatability, HaideliBikes spends a lot of money on mold engineering.

Prototyping frames are then made to be tested and evaluated. These prototypes are subjected to dimensional inspection, assembly tests and initial ride tests. The results of this stage can lead to geometry, layup, or structural fine-tuning before a full-scale test.

Testing and Quality Verification

Prototype frames are put through stringent laboratory testing before mass production is done. Impact tests, drop tests, vibration testing, fatigue testing, and stiffness testing are some of the tests that HaideliBikes conducts to ensure safety and durability. Internal defects that cannot be seen with the naked eye are detected by X-ray inspection to maintain the integrity of the frame’s structure of the frame.

These tests are simulated in the real-world conditions of riding and the use in the long run to ensure that every design complies with or surpasses the international standards of safety. A frame design only passes through these tests before proceeding to mass production.

Mass Production and Process Control

In mass production, HaideliBikes has a high level of process control so that all frames are identical. Layup, Molding, Curing, and Finishing are conducted under a controlled environment by highly trained staff. All processes are recorded and tracked to reduce variation and provide a repeatable quality.

Finishing, drilling, and Centering are done with accuracy to ensure conformity with the current components like disc brakes, electronic shifting system and UDH hangers. This is a disciplined way of scaling the production and still being at high standards by HaideliBikes.

Custom Paint and Finishing Options

Visual identity is equally important to clients of OEM as far as performance is concerned. HaideliBikes provides custom paint and finishes that match the brand aesthetics. The finishing process makes the object durable and attractive, with minimalist matte finishes and complex multi-color designs.

Adhesion of paint, smoothness of surfaces, and wear resistance over the long-term are all regulated to such a degree that the frames do not appear to be any different at the end of thousands of kilometers than when fresh.

Final Inspection and Delivery

All carbon bike frames are inspected last minute before being shipped. This takes place in terms of visual checks, dimensional verification and quality assurance reviews. Frames are then well-packaged to avoid any damage that is caused during international transportation.

HaideliBikes also offers documentation and support in assisting the brands in launching in the market, so that the transition between the factory and consumer is smooth.

Conclusion

Since its inception into large-scale manufacturing, the OEM carbon bike frame project of HaideliBikes has been developed on the basis of engineering and quality control, as well as close contact with other brands worldwide. Integrating the best design methods, yellow layup skills, extensive testing and quality manufacturing systems helps HaideliBikes to produce carbon frames that suit the market requirements of modern cycling. This quality and joint venture promise render HaideliBikes as a reliable OEM partner to any brand that wants to enjoy performance, reliability and longer success. This is an end-to-end model that will enable HaideliBikes to continuously translate innovative ideas into sustainable and high-performance carbon bike frames. Through the integration of technical know-how with receptive OEM partnerships, HaideliBikes will still help brands to create competitive and future-oriented cycling products.